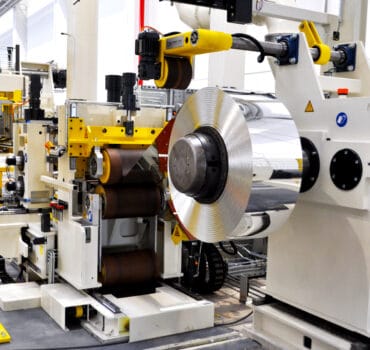

Slitting describes the technology in which a metal strip is cut into several narrow strips at the same time.

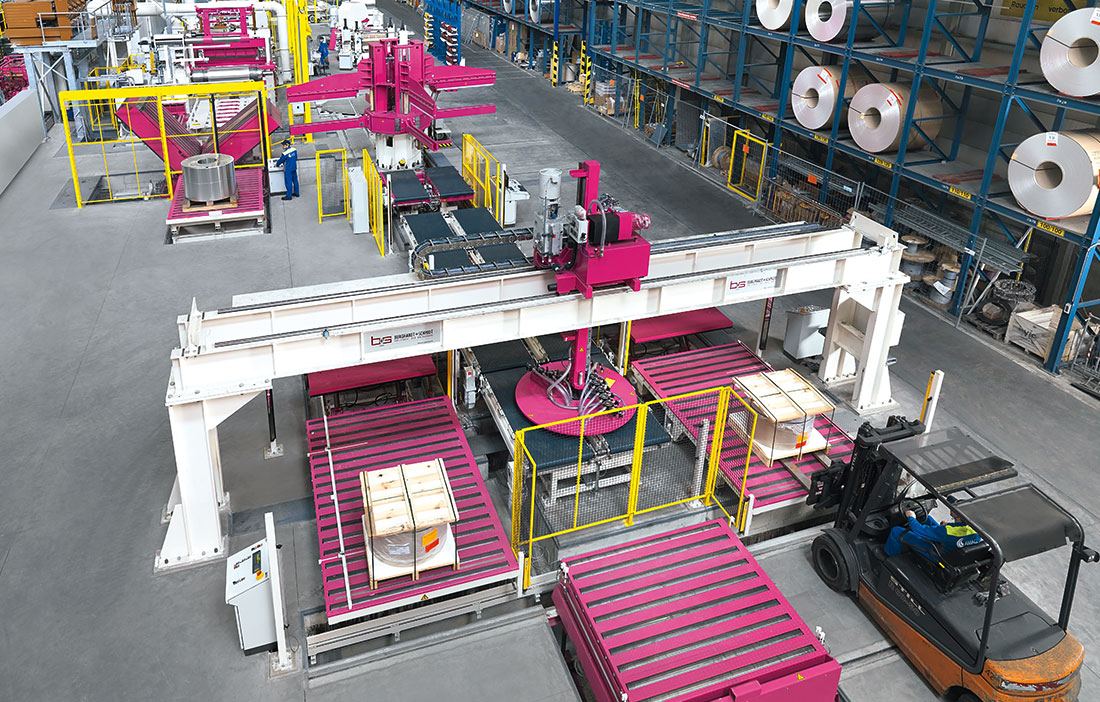

b+s is one of the world’s leading manufacturers of precision slitting lines for slitting and coiling thin and surface-sensitive metal strips.

Our slitting lines meet the highest requirements for precision and guarantee:

- best cutting quality,

- no surface damage,

- most accurate width tolerance and

- high winding quality.

In addition, all lines are always tailored to the individual needs of our customers.

The line speed, the design of the machines and the degree of automation depend on the estimated productivity of the line, the surface requirement, the strip thickness range, the strip width and the coil weight.

Take advantage of our many years of experience in cutting various materials such as copper, aluminum, steel, stainless steel, wire mesh, lead, gold, silver, palladium, molybdenum, tantalum, niobium, plastic, etc.

Line Specification

Our services include:

- detailed project consultation,

- customer-oriented kick-off meeting,

- in-house design office,

- intensive interaction between mechanical and electrical design,

- high value-added chain with in-house manufacturing and assembly,

Advantages of a b+s slitting line:

- High-precision cutting quality due to clearance-free slitter shaft bearings,

- Reduction of set-up times through innovative automation solutions as well as high line speeds,

- minimization of the degree of burr height with a simultaneously high number of strips due to the smallest possible deflection of the slitter shafts,

- exact winding pattern with increasing coil diameter due to a movable brake stand,

- no damage to the surfaces of highly sensitive materials due to innovative braking technology, such as vacuum brake roll,

- high energy savings due to state-of-the-art regenerative systems and use of energy-saving drives,

- Experience in processing ultra-high-strength materials with a tensile strength above 1,500 N/mm² and a yield strength above 1,100 N/mm².